Hydrolysis, the crumbling of shoe soles explained

Hydrolysis and polyurethane explained

Many of our shoes have the soles attached to the uppers by a process where 2 materials are brought together in a mould, the resultant chemical reaction forms polyurethane (PU). the use of polyurethane makes a lightweight flexible sole which is not only shock absorbent but also extremely hard wearing, that's why polyurethane is ideal for shoes.

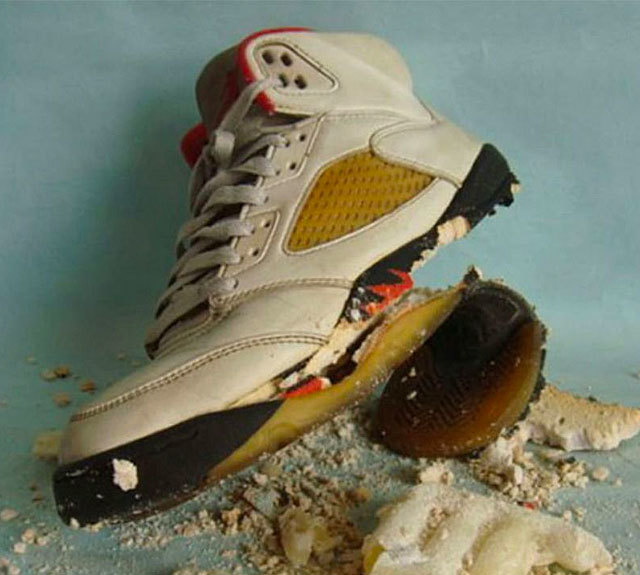

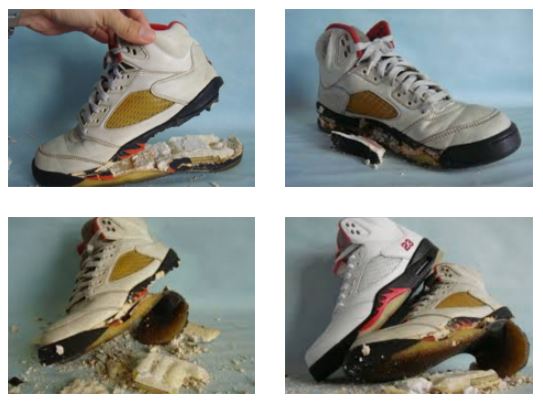

One of the main technical challenges with polyurethane is overcoming an ageing deterioration known as ‘hydrolysis’. Hydrolysis is the chemical breakdown of the PU polymer and the resulting physical breakdown or crumbling of the PU sole by the attack of water (usually in vapour form), occurring over a period of several years (even when the shoes are in store!).

This process is accelerated by warmth and high humidity. It will, therefore, happen more quickly in tropical climates, but also in confined spaces (such as lockers) if the safety shoes are put away damp. In the most advanced state of hydrolysis, the PU sole will lose all its physical strength, thus cracking or crumbling.

The Safety Jogger PU sole has been improved to increase the resistance against hydrolysis and performs better than any average safety shoe. Below you will read why!

The attack of hydrolysis on a regular PU sole

Safety Jogger products with PU sole

The Safety Jogger PU sole

There are 2 types of PU soles. There is a Polyether based PU sole and a Polyester based PU sole. Polyether based PU soles have a high resistance against hydrolysis and low oil resistance. Polyester based PU soles have a low resistance against hydrolysis and high oil resistance.

Safety shoes are always using a polyester based PU sole. The basic PU sole used in most safety shoes on the market lasts for 1.5 year in tropical conditions and 3 years in normal conditions.

The Safety Jogger PU sole, upgraded with improved resistance against hydrolysis, lasts for 4 years in tropical conditions and 8 years in normal conditions. Making our safety shoes a reliable product of endurance.

Do you have any questions about hydrolysis or crumbling shoe soles?

Don’t hesitate to contact us right away, We're social!

You might also like to read

Puncture resistant boots, steel vs. fabric midsoles

Puncture flesh wounds are particularly awful because screws, spikes, sharp scrap metal or the famous rusty nail puncturing the foot, can deposit bacteria and debris deep into the body.

Puncture resistant boots

The benefits of Lorica

Lorica takes its name from the Latin word “Lorica", meaning the armour of a Roman soldier. True to its name, Lorica is a high-performance synthetic microfiber that offers exceptional strength and durability. It looks and feels like premium leather but comes with added technical benefits, making it a top choice for demanding work environments where durability, comfort, and hygiene matter most.

LoricaGROW YOUR BUSINESS & BECOME A DEALER

Safety Jogger is worldwide and always looking for people who trust our brand as much as we do! We have a team of expert's ready for you to help with questions about our brand, technologies or reselling our products. So, don’t hesitate to fill in this form, we usually get back to you within a day!

Further information?

Fill in the form and we’ll get in touch!